What Industries Are Metal Laser Cutting Machines Used For?

Source:razortekcnc Time:2024-07-29

Metal laser cutting machine is the energy released when a laser beam is irradiated onto the surface of a metal workpiece, causing the metal workpiece to melt and evaporate, thereby achieving

the purpose of cutting. It has the characteristics of high precision, fast cutting speed, automatic typesetting, material saving, smooth cutting, and low processing cost.

Due to the emergence of metal laser cutting machines, productivity in the field of metal processing has been greatly improved. In addition, due to the high precision, small slit, fast speed, and

fast movement of laser cutting machines, the appearance of processed metals is much higher than that of traditional cutting machines, and almost no secondary processing is required.

What are the types of metal laser cutting machines?

Metal laser cutting machine is a laser cutting equipment specifically used for cutting and processing metal materials. At present, there are carbon dioxide laser cutting machines, fiber laser

cutting machines, and YAG laser cutting machines on the market.

Among them, high-power carbon dioxide laser cutting machines can cut metals, while the advantages of YAG laser cutting machines and fiber laser cutting machines are not very obvious. But

because fiber laser cutting machines are the latest laser technology with strong cutting capabilities and relatively low technical requirements, they are gradually becoming popular and

occupying the market.

So, what industries can metal laser cutting machines be applied to? Here is a summary of the main industries:

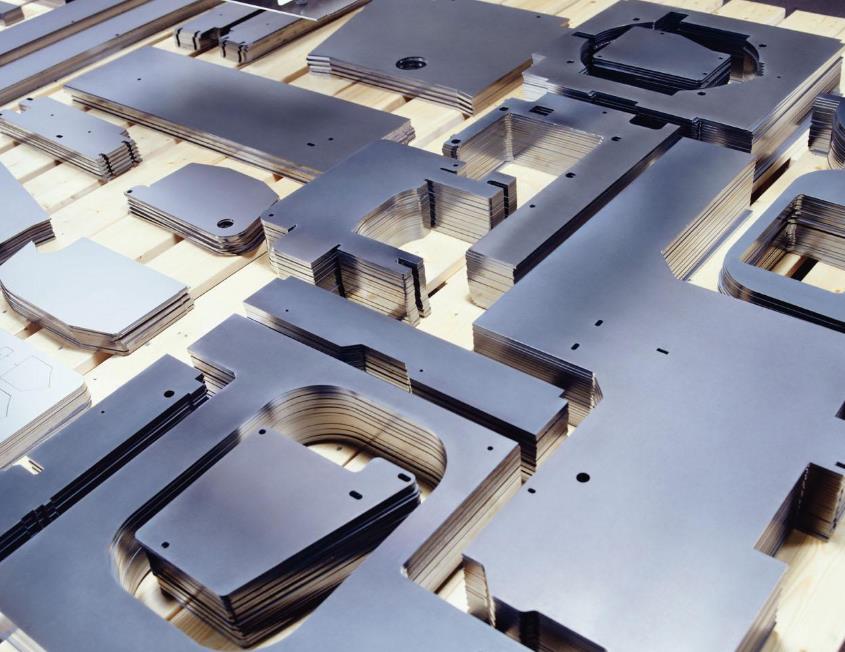

1. Sheet metal processing industry

Metal laser cutting machine is a major revolution in the field of metal sheet processing. Due to its high flexibility, fast cutting speed, high cutting efficiency, and short product cycle, sheet metal

laser cutting machines have become an indispensable machine in the sheet metal processing industry.

On the one hand, metal laser cutting machines have no deformation or tool wear during the processing. No matter what part it is, it can be accurately and quickly cut with a laser cutting

machine. On the other hand, metal laser cutting machines often have narrow cutting gaps, good cutting quality, and a high degree of automation.

2. Advertising metal character industry

In the advertising industry, more metal materials are usually used. Traditional processing equipment typically uses materials such as advertising fonts. Due to unsatisfactory machining accuracy

and cutting surface, there is a high possibility of rework. As a result, work efficiency is low and a significant amount of costs are wasted.

High precision metal laser cutting technology does not require secondary rework, greatly improving work efficiency and saving enterprise costs.

3. Kitchenware industry

In the kitchen processing industry, range hoods and gas appliances typically use a large amount of metal plates. When using traditional processing methods, it faces problems such as low

efficiency, high mold consumption, and high costs.

The metal laser cutting machine perfectly solves these problems. Fast cutting speed, high precision, improved processing efficiency, can achieve customized and personalized product

development, increase output, solve the problems of kitchenware manufacturers, and win the favor of kitchenware manufacturers.

4. Automobile manufacturing

There are also many precision parts and materials in cars, such as brake pads and doors. In order to improve the safety of vehicles, it is necessary to ensure cutting accuracy. However, traditional

processing methods or manual labor are difficult to ensure accuracy and efficiency.

Therefore, laser cutting can achieve rapid batch processing, high precision, high efficiency, no burrs, and one-time molding. That's why laser cutting machines are widely used in the automotive

industry.

As one of the most intelligent industries currently, the automotive manufacturing industry integrates multiple production processes. As one of the most important technologies, sheet metal

laser cutting machines have achieved intelligent production of up to 70% of parts.

5. Fitness equipment industry

The diversity of fitness equipment also puts high demands on processing, with multiple specifications and shapes making traditional processing complex and inefficient. Laser cutting is very

flexible and can be customized and processed according to different pipes and sheets. After processing, the finished product is smooth and free of burrs, without the need for secondary

treatment. Compared with traditional processes, the quality and efficiency are greatly improved.

6. Shipbuilding

In the field of shipbuilding, laser cutting of ship steel plates has good weld quality, good surface perpendicularity, no slag, thin oxide layer, smooth surface, no need for secondary processing,

direct welding, low thermal deformation, high curve cutting accuracy, reduced fitting time, and achieves high-strength ship plate unobstructed cutting.

7. Construction Machinery Industry

At present, the construction machinery industry needs to cut a large number of circular holes, square holes, and irregular holes on plates of various thicknesses, with high precision requirements.

Laser cutting can quickly drill holes and cut ideal shapes, greatly improving production efficiency and product quality.