How to Laser Cutting Metal Signs: A Guide to Laser-Cutting Metal

Source:razorteklaser Time:2024-08-28

Acquiring knowledge before laser cutting metal is essential for achieving optimal results. Before starting, make sure all necessary supplies and equipment are ready, and ensure that your workspace is clean and free of dust and debris to avoid interfering with the operation of the fiber laser metal cutting machine.

Preparation work:

Before marking with a laser cutting machine, the following tools and materials need to be prepared:

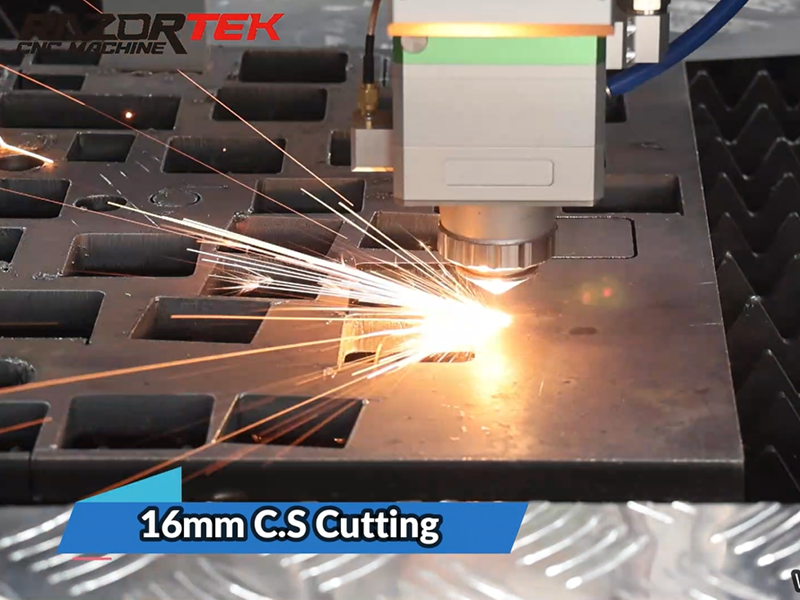

1. Laser cutting machine: Before starting cutting, make sure your fiber cutter is set up and working properly. This includes setting up gas cylinders for cutting, checking the water cooling system

for optimal circulation, adjusting the laser tube properly, and focusing the lens properly.

2. Marking computer: Install the marking software and familiarize yourself with its usage. Check the software to ensure that your design is displayed correctly on the computer. Before starting

the laser cutting metal process, you need to confirm that the design on the software matches the final product appearance you want.

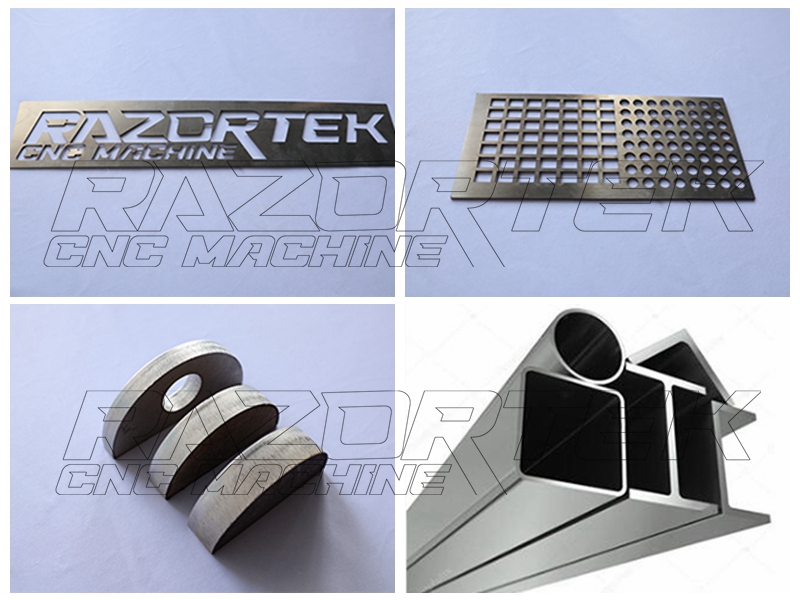

3. Marking materials: Choose according to your needs, commonly used materials include metal, non-metal, plastic, wood, etc.

4. Ordinary paper: used to test whether the laser parameters are set appropriately.

Choose appropriate marking materials:

Different laser cutting machines require the selection of different marking materials. For metal materials, it is necessary to use materials with special coatings engraved on them and require

higher power lasers. For non-metallic materials, ordinary printing materials or label paper can be used. When selecting materials, attention should be paid to the durability and marking effect of

the materials.

Set laser parameters properly:

The quality and effectiveness of laser marking are closely related to the setting of laser parameters. Before marking, it is necessary to set parameters such as laser power, marking speed, and

frequency to achieve the best marking effect. Generally speaking, the faster the marking speed and the higher the laser power, the better the engraving effect will be. But it also needs to be

adjusted reasonably according to the characteristics and requirements of the material.