For metal: Fiber laser marking machine and fiber laser cutting machine

Source:razorteklaser Time:2024-09-03

In the metal manufacturing industry, fiber laser metal marking machines and fiber laser metal cutting machines are both popular machines. They share similar basic working principles, but also have significant differences.

Just as fiber lasers have a wide range of applications, so do machines. The most important difference is that fiber laser marking machines are used for metal engraving, while fiber laser cutting machines are used for metal cutting.

The working principle of fiber laser:

Fiber laser refers to a laser that uses rare earth element doped glass fiber as a gain medium. Fiber lasers can be developed based on fiber amplifiers.

Fiber laser engraving machines and fiber laser cutting machines both use basic technology, with laser diodes used to convert electrical energy into photons, which are guided through fiber optic cables doped with quartz glass. Cables help focus photons onto a single path, which is introduced into a rare earth element that can amplify light and generate a laser beam. The intensity or wattage (W) of the laser beam is the main distinguishing feature between fiber laser marking machines and fiber laser cutting machines.

Fiber laser marking machine

As mentioned above, fiber laser marking machines are only used for engraving on materials, not cutting. This is because the wattage of the fiber laser engraving machine is between 20W and 100W, which does not meet the wattage threshold required for cutting metal. Although this may seem like a disadvantage compared to fiber laser cutting machines, it actually makes laser marking machines an ideal choice for the marking process. The use of lower power can better control the cutting quality, thereby achieving higher accuracy.

Fiber laser engraving machines can use various materials, including:

Stainless steel, silver, gold, titanium, aluminum, marble, brass, tiles, granite, hard plastic, acrylic, bricks, etc.

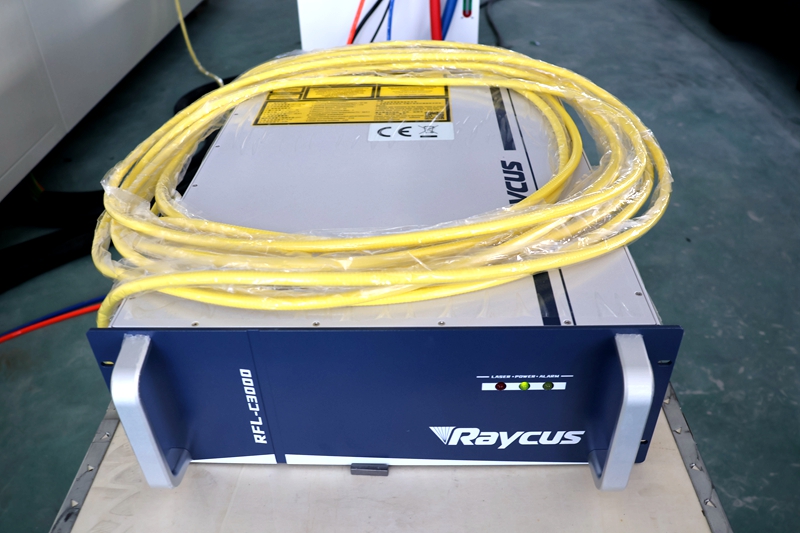

Fiber laser cutting machine

Fiber laser cutting machines are typically used for more industrial scale applications and are more powerful than fiber laser marking machines.

Unlike the short focal length lens of laser marking machines, laser cutting machines are equipped with medium focal length lenses. This makes its laser very suitable for cutting thick metals at maximum intensity, with a power range of 1.5 kW to 3 kW for fiber laser cutting.

Fiber laser cutting machines are used for various materials:

Cutting of metal sheets and pipes such as stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, aluminum zinc plated sheet, pickled sheet, copper, silver, gold, titanium, etc

Laser cutting machine can be applied in the following industries:

Gym/fitness, elevators, sheet metal processing, aerospace, electronic appliances, subway parts, automobiles, grain machinery, textiles, machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decorative advertising, metal external processing, kitchenware processing and other manufacturing and processing industries