Application of Fiber Laser Cutting Machine in Advertising Industry

Source:razorteklaser Time:2024-12-23

With the continuous development of society, the advertising industry has gradually matured, and processing equipment and technology have made significant progress. However, the overall profit of the advertising industry has declined, with overcapacity in the mid to low end and increasingly severe homogenization competition. Major advertising companies are seeking to break through. How to increase profits while occupying market share has become a difficult problem for advertising companies to consider and solve.

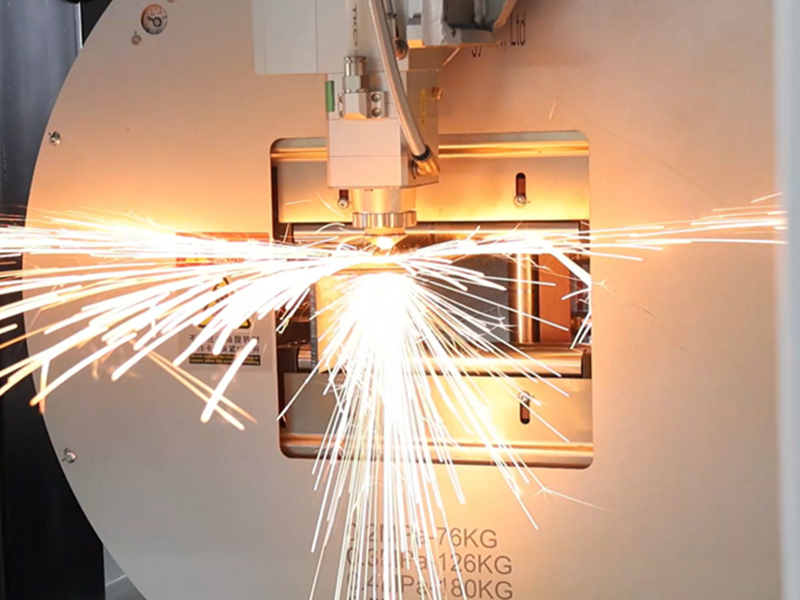

The development direction of the advertising industry, and the characteristics of advertising specific fiber laser cutting machines, are in line with this trend. With its excellent performance price ratio, it provides a strong guarantee for the profitability of advertising enterprises themselves.

The application of Razortek laser products in the advertising industry is already very experienced. Our fiber laser cutting machines have high cost-effectiveness, high configuration, high cutting efficiency, stable performance, and low operating costs.

The advantages of fiber laser cutting machine in the advertising industry:

1. Save material

Using computer programming technology, the product graphics of different shapes can be imported into the computer software system in advance, and the computer will automatically optimize the material layout and maximize the efficiency of material utilization.

2. Simplified program

Fiber laser cutting machine processing accuracy is much higher than other ways, so cutting edge smooth, one-time molding, no need for subsequent edge modification. At the same time, laser cutting can eliminate the opening process and improve the efficiency.

3. Saving investment in mould

Because it saves the opening process, it will reduce the consumption of mould, reduce the cost of production without repairing and replacing mould, and improve the market response speed of enterprise, aiming at the different cutting demand of different customers, it can respond quickly, especially suitable for multi-type and multi-batch production mode.

4. Protecting the Environment

Fiber laser cutting is an environmentally friendly process with less noise and no pollution. It also effectively solves the problem that companies cannot start work because of environmental problems. We can find that the production workshops with laser cutting machines are often cleaner and cutting waste less.