What materials can fiber laser cutting machines process?

Source:razortekcnc Time:2024-08-02

This article introduces which materials can be processed by fiber laser cutting machines.

Fiber laser cutting machine is a laser cutting machine that uses a fiber laser generator as the light source.

Fiber laser is a new type of fiber laser that outputs a high-energy density laser beam and focuses it on the surface of a metal workpiece, causing the spot of the workpiece to instantly melt and

produce gas after being irradiated with ultra-fine focusing. The automatic cutting is achieved by moving the spot irradiation position through a CNC mechanical system.

Types that can be processed by fiber laser cutting machines:

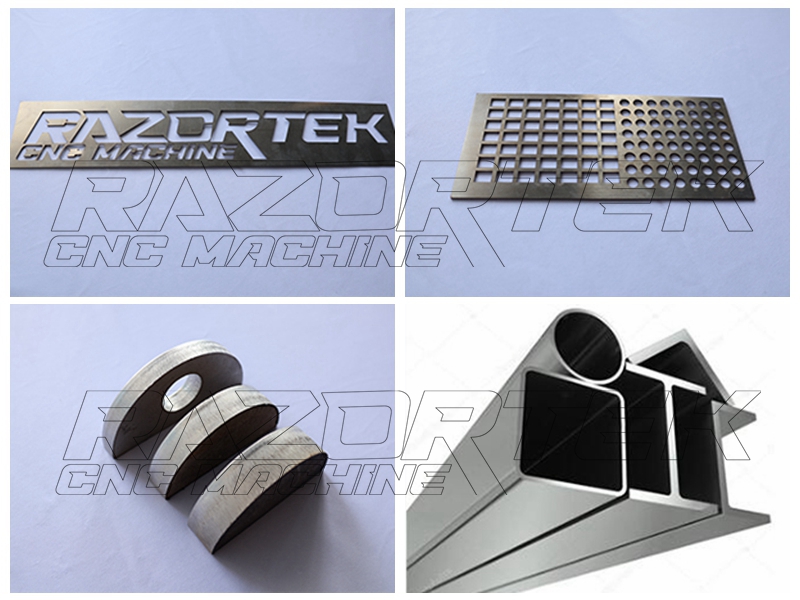

1. Metal components

Fiber laser cutting machine can cut and process various metal materials, such as carbon steel, stainless steel, aluminum alloy, copper, titanium, etc.

2. Non metallic components

Fiber laser cutting machines can also cut and process various non-metallic materials, such as quartz, ceramics, glass, rubber, paper, etc.

3. Special material components

Fiber laser cutting machines can also cut and process some special materials, such as alloys, composite materials, silicon wafers, semiconductors, etc.

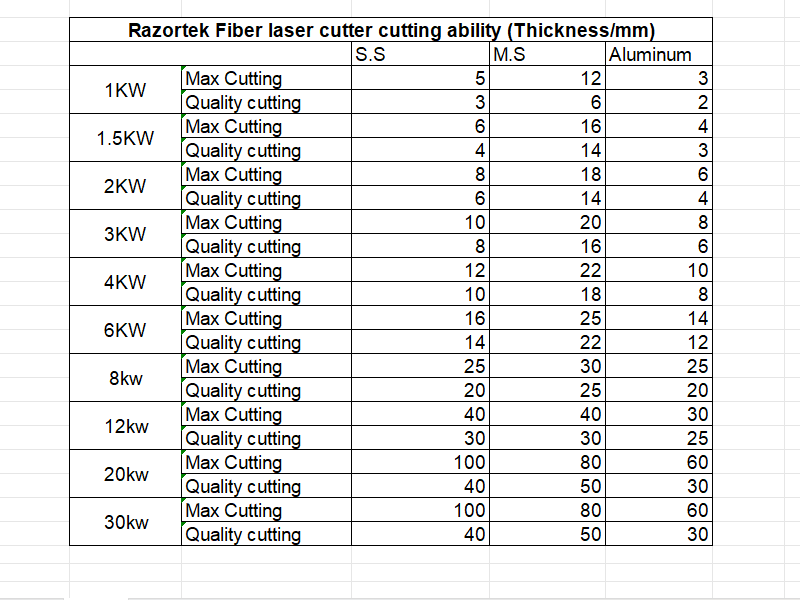

Technical parameters of fiber laser cutting machine:

Fiber laser cutting machines are widely used in various industries, and the following are some practical applications:

1. Mechanical manufacturing: Manufacturing various machine parts, mold parts, gears, etc.

2. Metal processing: sheet metal cutting, manufacturing of metal structural components, etc.

3. Electronics industry: Manufacturing circuit boards, mobile phones, and accessories.

4. Construction industry: Manufacturing decorative components, outdoor billboards, etc.