How To Maintain And Extend The Service Life Of Fiber Laser Cutting Machines?

Source:razorteklaser Time:2024-11-25

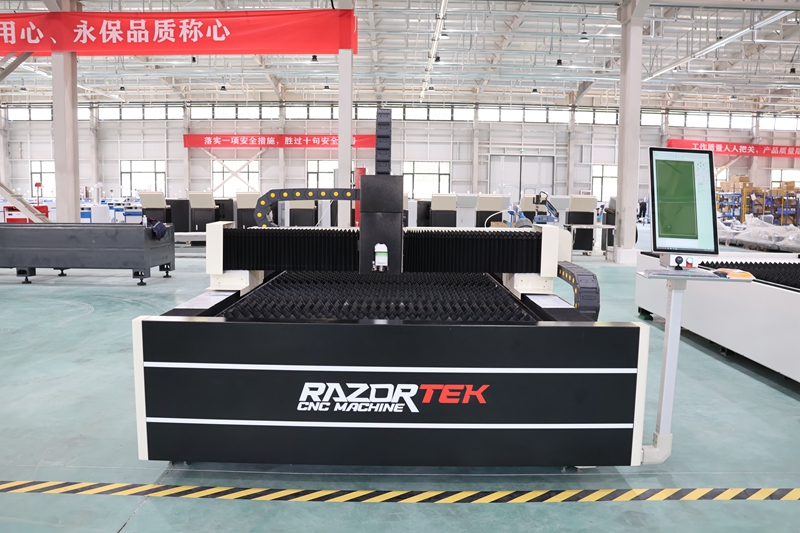

Fiber laser cutting machines are widely used in the manufacturing industry and have the characteristics of fast cutting speed, high precision, and high efficiency. However, like any other

industrial equipment, these machines require proper maintenance to ensure optimal performance and lifespan. This article lists some basic techniques for maintaining and extending the

lifespan of fiber laser cutting machines.

1. Regular cleaning and inspection

Regular cleaning is crucial for keeping the fiber laser cutting machine in optimal condition. Dust, debris, and metal shavings can accumulate on machine components, leading to performance

issues and potential damage. Regularly clean and inspect the optics, lenses, nozzles, and other critical components of the machine to prevent accumulation and maintain cutting quality.

2. Lubrication and calibration

Proper lubrication of moving parts such as bearings, rails, and gears is essential to reduce friction and wear. Follow the manufacturer's lubrication interval guidelines and use high-quality

lubricants. In addition, ensure accurate calibration of the machine to maintain cutting accuracy and consistency.

3. Monitoring the cooling system

Fiber laser cutting machines generate a large amount of heat during operation. Monitoring and maintaining the cooling system, including coolers and heat exchangers, is crucial to prevent

overheating and ensure stable operating temperatures. Regularly check the coolant level, overall condition of filters and cooling components.

4. Software updates and maintenance

Keep the control software and firmware of the machine updated to benefit from performance improvements, error fixes, and new features. Regularly check for updates and perform software maintenance according to the manufacturer's recommendations to ensure optimal functionality and security.

5. Operator training and safety

Proper training for machine operators is crucial for equipment maintenance and preventing avoidable damage. It is essential to ensure that operators are proficient in machine operation, safety

procedures, and maintenance protocols. Encourage a culture of safety and responsibility to minimize the risk of accidents and equipment misuse. Razortek provides after-sales training services

to ensure the correct use of machines, thereby extending their lifespan and improving your production efficiency. In addition, our engineers can provide on-site training for customers to ensure

they are proficient in operating the machines.

6. Regular preventive maintenance

According to the manufacturer's recommendations, implement regular preventive maintenance plans. This may include regular inspections, component replacement, and performance checks by

qualified technicians to identify and resolve potential issues before they escalate.

7. Environmental precautions

Keep the working environment of the fiber laser cutting machine clean and well ventilated. Controlling dust, humidity, and temperature levels helps prevent premature wear and corrosion of

machine components.

Following these guidelines can ensure that fiber laser cutting machines operate at their best and extend their lifespan. Proper maintenance not only helps avoid expensive repairs and downtime,

but also maximizes the production efficiency and cutting quality of the machine.