Application of Laser Cutting Machine in Aerospace Field

Source:razorteklaser Time:2024-11-27

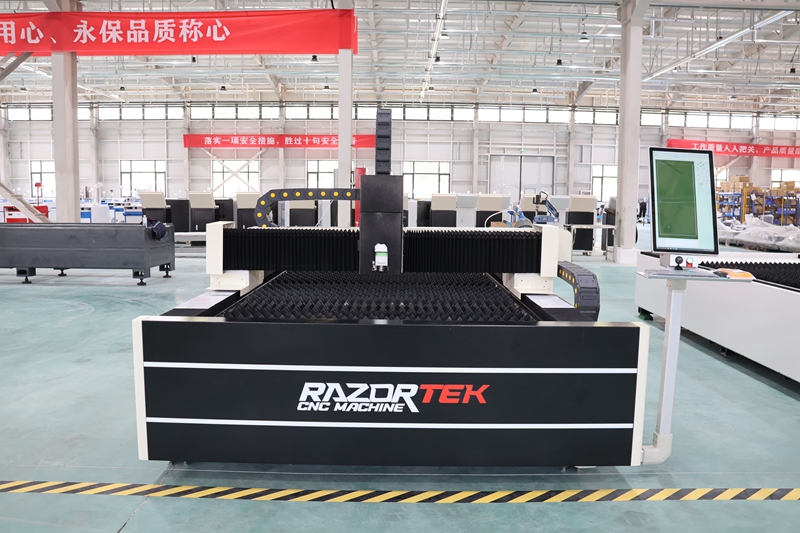

The aerospace industry is a technology intensive and high demand field, involving the manufacturing of numerous complex components and precision structures. Laser cutting machine, as an

advanced processing equipment, has been widely used in the aerospace industry. This article will introduce the application and advantages of laser cutting machines in the aerospace industry.

Application of laser cutting machine in aerospace industry

1. Manufacturing of aircraft components:

Aircraft manufacturing is an important component of the aerospace industry, involving the manufacturing of various aircraft components. Laser cutting machines can quickly and accurately cut

various aircraft components, improving manufacturing accuracy and quality. Meanwhile, the non-contact processing method of laser cutting machines can avoid the problems caused by

traditional processing methods, such as tool wear and thermal deformation.

2. Manufacturing of rockets and satellites:

Rockets and satellites are another important component of the aerospace industry. Laser cutting machines can be used to manufacture key parts such as shells and structural components of

rockets and satellites, improving manufacturing accuracy and quality. Meanwhile, the non-contact processing method of laser cutting machines can avoid the problems caused by traditional

processing methods, ensuring the safety and reliability of rockets and satellites.

3. Aviation maintenance and renovation:

In the aerospace industry, aircraft maintenance and modification are important links. Laser cutting machines can quickly and accurately complete these tasks, extending the service life of

equipment and improving production efficiency by locally repairing and replacing aircraft components.

The advantages of laser cutting machines in the aerospace industry

1. High precision

Laser cutting machines have high precision and can achieve precise cutting of various materials. Meanwhile, laser cutting machines can also achieve automated and intelligent cutting through CNC systems, reducing human errors and improving cutting accuracy and quality. This high-precision cutting method meets the high standard requirements for component manufacturing in the aerospace industry.

2. High speed

The speed of laser cutting machine is very fast, which can greatly shorten the production cycle and improve production efficiency. Manufacturing in the aerospace industry typically has strict

time requirements, and the fast cutting capability of laser cutting machines helps to complete production tasks on time.

3. Environmental protection and energy conservation

The laser cutting machine adopts non-contact processing method, which will not produce noise, vibration, pollution and other problems. In the manufacturing process of the aerospace industry,

environmental protection and energy conservation are important considerations, and the green processing method of laser cutting machines meets this requirement.

4. Widely applicable materials

Laser cutting machines are suitable for cutting various metal and non-metal materials. In the aerospace field, various materials are needed to manufacture components and structural parts, and

the wide applicability of laser cutting machines provides convenience for their application in the aerospace field.

5. Low maintenance cost

The maintenance cost of laser cutting machines is relatively low, and daily maintenance only requires the replacement of vulnerable parts such as air filters, making maintenance convenient and

cost-effective. Meanwhile, the long service life of laser cutting machines reduces the frequency of equipment updates and further lowers maintenance costs.

In summary, laser cutting machines have broad application prospects and advantages in the aerospace industry. It can improve the production efficiency and quality of the aerospace industry,

reduce manufacturing and maintenance costs, and promote the development and progress of the aerospace industry. With the continuous development of technology, the technical level of

laser cutting machines will also continue to improve, providing stronger support for the development of the aerospace industry.